The boom in ecommerce sales has a dark side effect: online returns alone cost UK retailers an estimated £5.2bn a year. These costs are a combination of issuing a refund and the reverse logistics required to receive and process the return.

Reverse logistics is the process of returning goods and materials back to the original manufacturer or supplier. In many cases, businesses incur additional costs to manage and process returns. As a result, optimising reverse logistics can help businesses reduce these costs and improve the bottom line. When processes are strategically optimised, brands increase the likelihood that undamaged, returned product can be re-sold at full price.

However, it is not just profit that businesses lose out on with returns. Reverse logistics can also increase a company’s environmental impact. Not only are brands impacting the environment when an order is initially shipped to a customer, but the impact is essentially doubled if the customer returns the package. Then, of course, the are the effects of disposal. In the fashion industry, thousands of pounds of returned goods end up in landfills each year. Retailers dispose of approximately one-quarter of returned goods. In the U.S., that equals nearly 6 billion pounds of waste annually.

It is no wonder that many organisations are looking for innovative ways to reduce the impact of returns. Optimising reverse logistics can help reduce the impact on an organisation’s bottom line and its carbon footprint.

What Are Reverse Logistics?

Reverse logistics is the process of moving a product at least one step backwards through the supply chain. In retail and ecommerce, customers may return a product for many reasons, such as damage, defects or simply because the customer changes their mind.

How a company chooses to handle reverse logistics can either drain revenue and resources or provide an opportunity to win more business. Poorly thought though and opaque returns policies and processes erode customer trust and reduce loyalty. However, strategic, transparent and optimised reverse logistics can improve customer loyalty and customer lifetime value.

Reverse logistics entail dozens of different operations in an organisation, but many refer to the core group as the 5 Rs: returns, reselling, repairs, remanufacturing and recycling.

Returns management

This is the process of managing the return of goods. It includes the inspection of returned goods, determining whether they can be resold and arranging for their return to the supplier. For some companies, reselling is possible and also profitable. In others, such as fashion, it can be very difficult to resell an item, especially if it costs more to clean and restock than it would to dispose of it and create a new one.

Reselling

Some items can either go right back on the shelf or can return with a little bit of work. Companies can either decide to create a policy where returns are inspected and tested and resold or they are sold as-is for a discount. Sometimes, retailers may set up a distinct ecommerce channel dedicated to the resale of returned merchandise. This strategy lets brands offer discounts without diluting brand reputation.

Repairs and maintenance

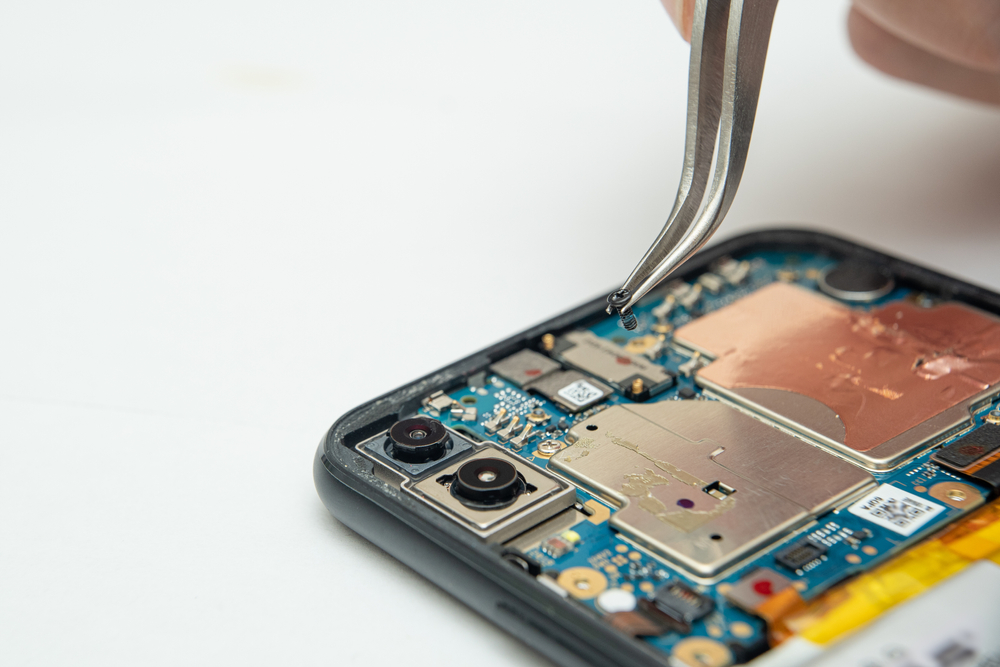

For some luxury clothing and accessories or big-ticket electronics, manufacturers and retailers offer repair and maintenance services. These services keep goods in the hands of consumers longer and can even keep items in good enough condition to be passed down to children and grandchildren. In some cases, repairs and maintenance are done by the manufacturer or a third party steps in for convenience and cost savings.

Remanufacturing or refurbishment

This is the process of repairing or cleaning returned goods for resale. This can be done by the manufacturer or by a third party. Remanufactured items can be split into their component pieces and reused for a new item. Refurbished goods like electronics are frequently sold at a discount or offered to customers if they return an item within a warranty period as a replacement.

Recycling

Materials such as chips, metal or even fibres can be recycled and made into something new. Within a single electronic device, copper, circuit boards and batteries are all recycleable. Other items such as textiles can be recycled to create cushion and pillow stuffing, insulation, cloths and paper.

Each of these categories of reverse logistics can have a measurable impact on an organisation, including boosting profits and minimising losses.

Why Do Reverse Logistics Matter?

Minimising losses is one of the most important drivers for many retailers. However, optimising reverse logistics has plenty of other benefits, including a reduction in environmental impact and offering goods another opportunity to turn a profit.

In fact, reselling returned items is becoming more popular and less stigmatised. According to a recent poll, 95% of consumers would be willing to purchase resale items directly from a brand at a discount. Other reasons to consider taking a second look at your reverse logistics processes include:

- Cutting down on waste and unused inventory by better understanding a customer’s buying preferences.

- Building goodwill with customers by showing that they care about the environment and their products.

- Keeping down storage costs for damaged inventory.

- Faster and better service for customers who want to return items as well as those who would like to purchase returned items.

- Improving customer retention with innovative ideas and seamless return and purchasing processes.

However, another significant way retailers can simplify their reverse logistics is by preventing the returns from happening in the first place.

How to Reduce Returns in Retail

Many consumers are skipping the in-store experience and instead purchasing clothing, sometimes multiples in different sizes or colours, to bring the fitting-room experience home. However, this has accounted for ballooning return rates that are quickly eroding profits and wreaking havoc on logistics processes.

Some retailers are stopping returns at the source. A few ideas include:

- Keeping on top of product descriptions to ensure they are accurate and complete. This includes specifying dimensions, materials, care instructions, etc. Customers should know exactly what they are getting before they make a purchase.

- Offer a wide range of product photos. Customers should be able to see the product from all angles, in different lighting, etc. This will help them get a better sense of what the product looks like in real life. Additionally, technology such as augmented reality can allow a customer to see furniture in their room before they purchase it. Down the road, digital fitting rooms could enable customers to see a look on their virtual selves before making a purchase.

- Charging customers for a return. Customers value free shipping and simple return policies when looking for an online retailer, so this tactic does come with some risk. However, some retailers charge customers for returns for online purchases while not imposing that fee on customers who return their items in-store.

The Bottom Line

Returns are an expensive part of retail business – both in terms of dollars and environmental impact. Meeting customer demands while protecting the business reputation and balance sheet involves imagination and some risk. But the benefits of implementing smarter reverse logistics strategies may be what separates the ecommerce winners from the losers.

When expanding business across your domestic borders, optimised reverse logistics are a must. When you’re ready to take your brand to new markets while providing a superior customer experience and seeing a boost in revenue, ESW can help. We offer reverse logistics support that enables retailers and brands to handle returns in the best way for your customers and your business model.

Contact us today to learn more about how you can explore a new way of thinking about reverse logistics.